On October 10, a devastating explosion took place at the Accurate Energetic Systems (AES) facility in Bucksnort, Tennessee, resulting in the tragic deaths of 16 employees and injuring at least four more.

Officials from the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) and the National Center for Explosives Training and Research estimated that between 24,000 and 28,000 pounds of explosives detonated, completely demolishing the 15,000-square-foot building. The impact resembled the effects of a massive U.S. MOAB or MOP bomb, known as two of the heaviest non-nuclear weaponry in the military’s arsenal.

This article will explore the immediate causes of the explosion, contributing factors, and how this disaster reflects the broader implications of America’s military endeavors abroad and domestic social policies.

Immediate Cause

According to early investigations, several hypotheses have been proposed about the explosion’s cause, although specific details remain undisclosed. Jamey VanVliet, a special agent with the Nashville ATF office, declined to speculate on potential causes. He mentioned, however, that there was no immediate threat to public safety, and the origin of the blast appeared to be the lower production floor of the pouring and casting facility.

“The initial explosion occurred in one of those production kettles,” explained VanVliet. “We believe that in addition to that, there was a sympathetic detonation of other explosive materials stored in that same area,” as stated by local official McCracken.

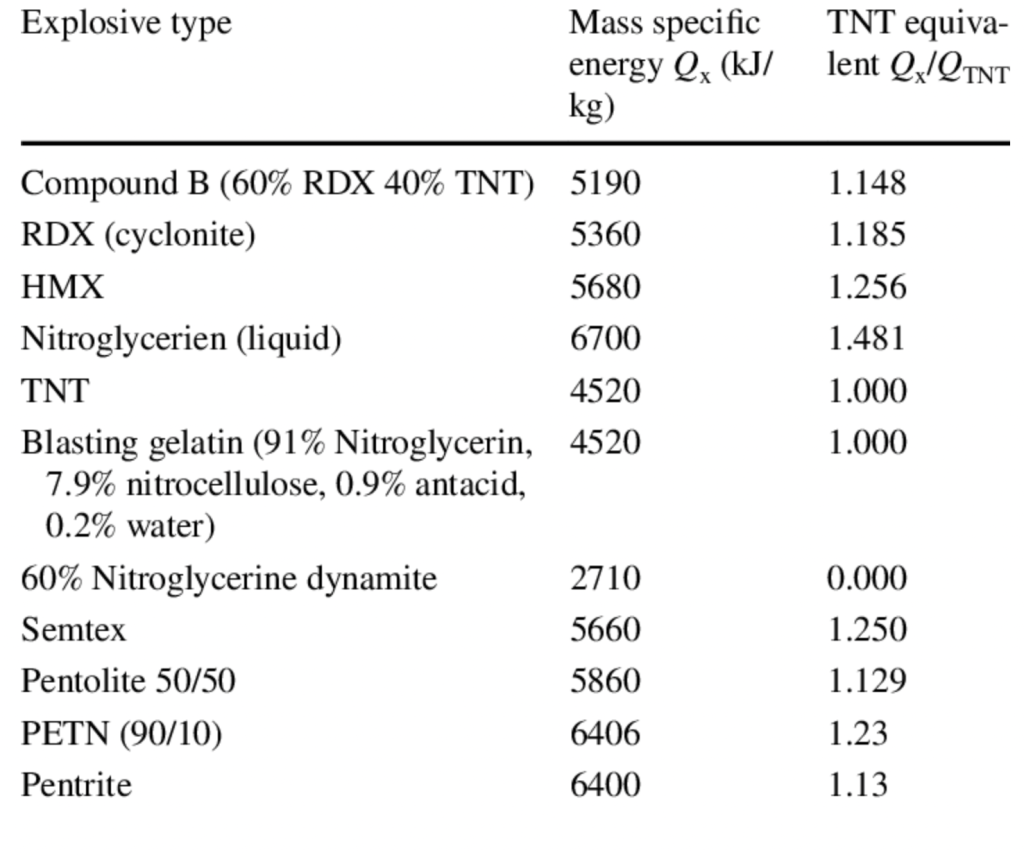

The facility specialized in manufacturing cast boosters for both commercial mining and military applications, commonly comprising a mixture of TNT and RDX.

Here’s some relevant background on cast boosters, sourced from the Big Chemical Encyclopedia:

A cast booster is a sensitive explosive charge that connects a traditional detonator with a low-sensitivity, high-energy explosive like TNT. Alone, a conventional detonator lacks the energy to initiate the low-sensitivity charge. Instead, it ignites the booster, which in turn creates a shockwave powerful enough to detonate the main explosive charge.

Cast boosters are typically formed from a mix of TNT and PETN or RDX and are poured into molds to solidify. From a performance perspective, cast boosters are often favored for their high detonation pressures, insensitivity, water resistance, and ease of initiation.

Contributing Factors

While the official cause is still pending, several contributing factors have emerged that may have heightened the explosion’s likelihood.

TNT Shortages and Alternatives

As reported by the New York Times, the production of TNT in the U.S. has heavily relied on foreign suppliers for decades, notably from China, Poland, Russia, and Ukraine, especially since the last U.S. government-owned plant closed in the 1980s. The ongoing conflict in Ukraine, which escalated in 2022, has created significant pressure on TNT supplies, leading to shortages in the U.S.

Earlier articles even dated back to September 1, highlighting the growing scarcity of TNT in the American context. A critical source of TNT had been the reclamation of old munitions, but the military’s decision to retain these assets has restricted availability.

Poland had previously been the Pentagon’s primary authorized supplier but has redirected much of its production to Ukraine. Additionally, both Russia and China have ceased their exports to the United States.

The issues caused by U.S. foreign policy may have unintentionally aggravated the situation. In response, the U.S. has turned to riskier explosives while also relaxing standard safety protocols, as highlighted by the New York Times, which noted that “all of this has pressured U.S. weapons production,” leading to the tragic incident in Bucksnort.

What does U.S. supply constraints mean for AES? The company is believed to be the leading American manufacturer of TNT for artillery shells, although the specifics of their supply chain remain unclear amid escalating conflicts abroad.

Reports indicate that AES faced severe challenges in keeping up with the demands of military production in light of Russia and Ukraine’s ongoing war.

The PETN Connection

As a substitute for TNT, the U.S. has increasingly relied on pentaerythritol tetranitrate (PETN), manufactured in a limited number of American factories, with AES among them. According to the archived version of the AES website, the company also produces various other explosive materials sought after by both government and commercial sectors.

Specifically, AES manufactures PETN, which holds multiple applications, ranging from detonating cords to mining uses.

PETN, while more expensive and complex to handle compared to TNT, is also significantly more powerful. It is recognized for its use in military applications but carries greater stability concerns, making it potentially riskier in manufacturing contexts.

In 1989, an incident at Atlas Powder Company in Joplin, Missouri involving PETN exemplifies these risks:

The plant was involved in producing pentolite, and during a mixing operation involving TNT and PETN, workers inadvertently caused an explosion resulting in fatalities and injuries.

The increasing demand for PETN is apparent in its application for modern asymmetrical warfare scenarios.

In military strategies, PETN has been adapted for various explosive applications, often molded into plastic explosives that can be concealed in everyday objects.

While it cannot be confirmed that PETN was involved in the Bucksnort explosion, it is reasonable to conjecture that it may have played a role due to AES’s production adjustment to meet TNT shortages. The explosion originated from a production kettle used for combining explosives to form a cast booster, raising safety concerns associated with PETN’s characteristics.

With Conflict Escalating, Safety Takes a Backseat

The reliance on private firms like AES for explosives production has become a pervasive concern. As Military.com notes:

The Tennessee explosion is a manifestation of a long-standing issue in America: as demand for weaponry surges, production consistently outpaces safety oversight, transferring risks from battlefields to production floors.

Safety breaches were not new at the AES facility, evidenced by a previous explosion in 2014 that resulted in both fatalities and injuries, showcasing a historical pattern of neglect in safety protocols.

Despite multiple citations for inadequate safety measures, the company faced minimal repercussions.

The socioeconomic context of Hickman County, where AES is located, reveals a troubling reality. With a per capita income of just $29,512 and a poverty rate exceeding 14%, it is indicative of the regions that bear the brunt of risks in arms manufacturing.

The investments made in munitions could instead redirect resources towards community development, improving living conditions for local populations.

As Washington continues to allocate significant funds toward military activities, the Bucksnort explosion serves as a grim reminder of the domestic ramifications of these choices. It highlights the stark reality of how military profiteering does not just inflict harm abroad but also brings danger to local communities.