The state of US manufacturing has been under intense scrutiny, with experts like Steve Keen expressing a grim outlook on its future. He recently shared a compelling YouTube video that argues why the decline of American manufacturing is likely to be permanent. The video’s insights extend beyond the recurring theme that the revival of US industrial capacity requires substantial and sustained policies, including more than just tariffs. This issue is steeped in nostalgia for a time when manufacturing was a robust source of middle-class jobs— a scenario that has largely changed due to increasing automation and technological advancements that require fewer workers.

How Superpowers Die: The 5 Stages of Industrial Collapse https://t.co/ZC0nL9Fzvm via @YouTube

— Dr. Steve Keen (@ProfSteveKeen) November 1, 2025

Two major barriers complicate the enactment of industrial policy in the US. First, there exists a deep-seated reluctance to pursue aggressive industrial strategies, often leading to a default reliance on subsidies and tax incentives targeted at politically influential sectors, including healthcare, defense, banking, real estate, and higher education. A case in point is Biden’s Inflation Reduction Act, which attempted a patchwork approach to meet diverse goals but fell short on effectiveness.1

The second obstacle is the US’s historical inability to maintain consistent economic policies over extended periods, except in times of extreme national urgency like World War II. A genuine large-scale rebuild of US manufacturing would necessitate a commitment spanning at least ten years, assuming it could be achieved at all.

While the video offers a brief historical overview, it oversimplifies several points and occasionally presents inaccuracies:

It rightly notes the beneficial ripple effects stemming from strong manufacturing capabilities, such as advantages for suppliers; however, it misleadingly implies that manufacturing still creates a significant number of high-paying jobs. For instance, recent data from China indicated a staggering youth unemployment rate of 21.3% when the country paused publishing employment figures in 2023. Even after revised methodologies, this number stood at 18.9% in August and 17.7% in September.

The increasing prevalence of highly automated factories, including those functioning entirely without human presence—termed “dark factories”—has severed the traditional link between manufacturing and job creation. Here’s a summary about dark factories:

1. What is a Dark Factory?

- A dark factory is a fully automated production facility that operates without requiring human intervention.

- These factories maintain a low-light environment since robots and AI systems do not need visibility.

- They utilize artificial intelligence, integrated IoT systems, and robotics to handle tasks ranging from material management to product assembly.

2. How Do Dark Factories Operate?

- AI-driven robotic systems autonomously manage the production lines.

- IoT connectivity ensures smooth communication between machines, allowing for predictive maintenance and self-regulation.

- Automated logistics manage inventory and transportation of goods independently of human input.

3. Why Are Dark Factories Gaining Traction?

- Enhanced production efficiency—Machines run continuously, significantly reducing downtime.

- Reduced operational costs—The absence of human workers lowers wage expenses and decreases energy usage.

- Consistent quality assurance—AI ensures precise manufacturing and the production of defect-free products.

Additionally, here’s a video showcasing one of these dark factories in action:

Another informative video on this topic unfortunately could not be embedded.

Ironically, many supposedly cutting-edge US factories are lagging behind. For example, Hyundai inaugurated a “factory of the future” in Georgia in 2025, initially hiring about 1,200 workers with plans to expand to 8,500 as production ramps up to 500,000 vehicles annually.

These numbers pale in comparison to historical workforce levels. Ford’s Rouge plant boasted 120,000 workers during World War II, a figure augmented by its completely integrated facilities that even produced steel. Thus, even if the US could restore manufacturing capabilities on a significant scale, the potential for substantial job growth would remain limited.

Furthermore, Keen’s video simplifies the reasons behind the decline of US manufacturing. In my experience during business school in the late 1970s, both the media and academia recognized the sluggishness of US management, particularly within automotive companies. While they acknowledged that Germany and Japan benefited from new infrastructure post-World War II, the reluctance of American firms to abandon or modernize their existing investment-heavy operations hampered progress. Additionally, regional biases regarding vehicle types further clouded the judgment of industry leaders. Meanwhile, personal experiences with vehicles insulated executives from everyday consumer issues like product quality complications. Moreover, ingrained notions of US exceptionalism and racial biases often led to a disbelief that foreign competitors could surpass domestic production until it was too late.

The decline of American car manufacturers was accelerated by a significant rise in the dollar’s value in the early 1980s—following a period of super-high interest rates under Volcker—which shifted market dynamics and allowed Japanese automakers to capture significant market share that they retained thereafter.

The Keen video also misrepresents labor costs in the steel industry as a primary factor in its decline. Steel production is characterized by a continuous manufacturing process, where capital and raw materials primarily influence costs over labor. In fact, the outdated infrastructure of US steel mills, coupled with limited modernization investments, has been detrimental to their competitiveness. This trend has also been observed in the paper industry, where long-lived machinery often faces downsizing or closure due to lax investment in maintenance and upgrades.

The video fails to address why the decline of US manufacturing, and the challenge of reversing it, seems inevitable. The overarching claim is that once a nation falters in the innovation race, recovery is unrealistic.

However, there are several reasons why a revival of US manufacturing appears implausible:

1. **Deteriorating Public Education and Performance**: According to a 2024 report from The Balance:

The United States currently invests less in human capital than its developed counterparts, resulting in a waning competitive edge, particularly in educational rankings.

US students’ math skills have stagnated for decades, while other nations such as Japan, Poland, and Ireland have made significant strides. Additionally, US test scores fall short of the global average. Here’s the breakdown:

Key Takeaways

- The US placed 16th out of 81 countries in science during the last examinations in 2022.

- All five top-performing countries in math scores in 2022 were Asian.

- US student math scores have remained static since 2003, with science scores similarly stagnant since 2006.

- According to the IMD World Competitiveness Center, the US ranked 12th in its 2024 Competitiveness Report, down from first place in 2018.

This data might underestimate the real challenges. For instance, I’ve encountered reports from readers who have observed young retail applicants struggling with basic tasks like giving change. In a different context, a medical colleague noted that summer program students from elite medical schools seemed overly reliant on AI and search engines, lacking essential independent knowledge and clinical judgment.

2. **Lack of Career Opportunities for Technical and Engineering Graduates**: For over 20 years, graduates in these fields have faced limited job prospects. I’ve heard that petroleum engineering remains one of the few disciplines offering decent job opportunities; for others, the financial burden of obtaining degrees does not align with potential earnings, unless students pursue advanced law degrees to work as patent lawyers.

3. **Decreased Prestige of Manufacturing Management Roles**: Many might choose alternative lifestyles over pursuing careers in manufacturing, which often require relocation to less major cities. While some may appreciate the benefits, this mindset discourages talent from entering the field.

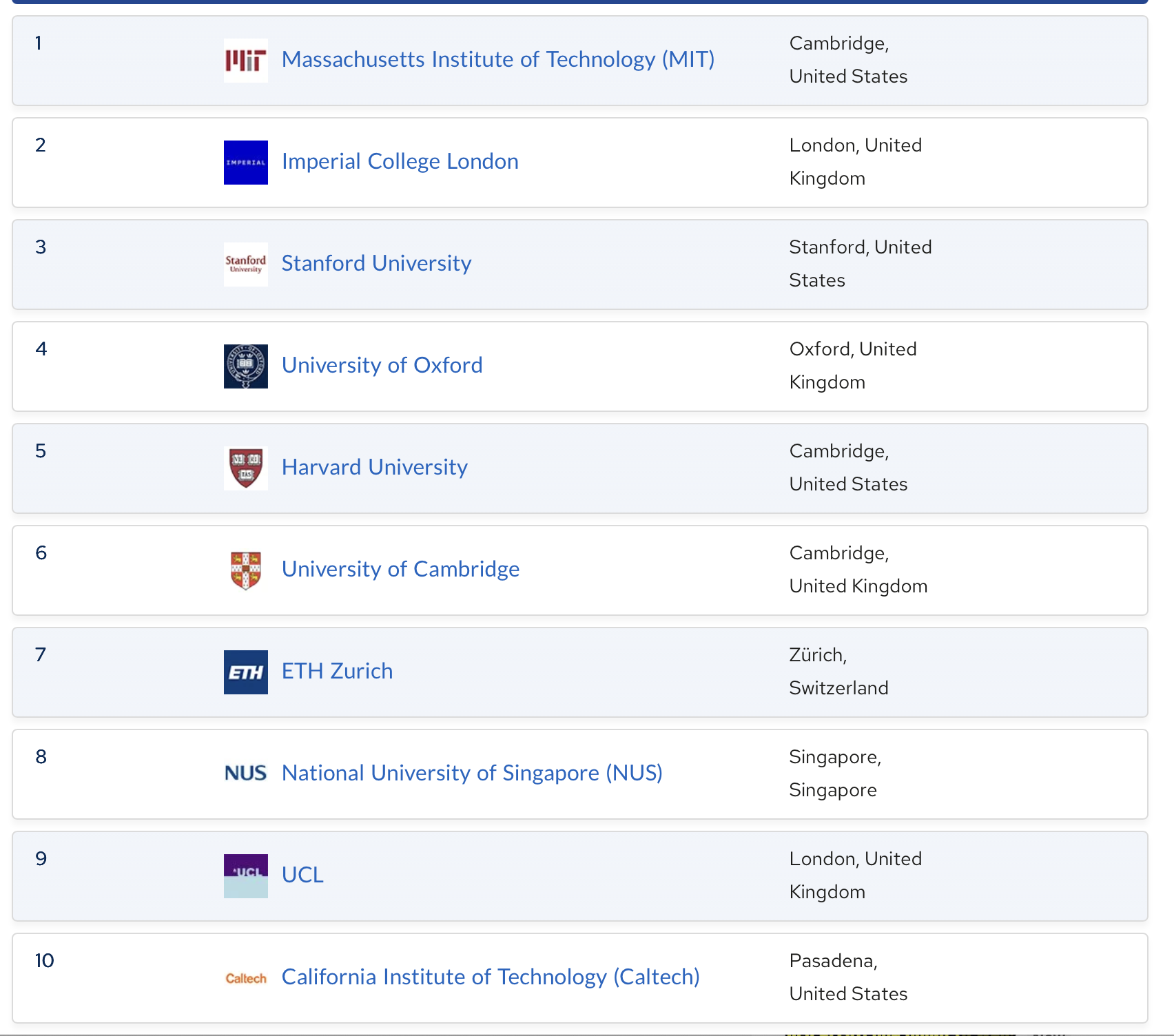

4. **Erosion of Academic Advantage**: The political climate has also skewed perceptions of elite universities, particularly during the Trump administration, with initiatives undermining their reputation. A QS ranking suggests Western institutions remain at the forefront, while others confirm similar findings.

Similar assessments from other rankings highlight these challenges.

:

:

This analysis underscores that, even with continued Western dominance in academia, the practical applications are diminishing, reflecting stark realities like a declining life expectancy in the US.

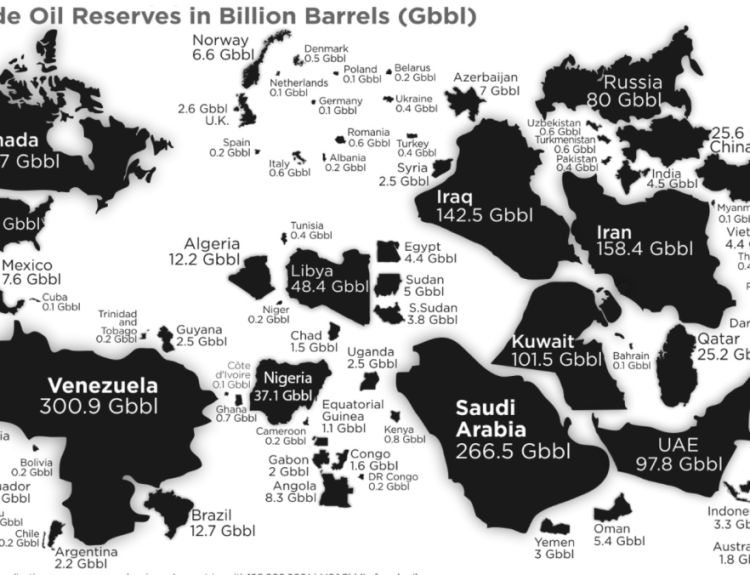

5. **Resistance to Manufacturing’s Environmental Cost**: The US is unlikely to accept the pollution burden associated with a major manufacturing revival. Concerns surrounding rare earth mining illustrate the point—once a leader in this domain, the US significantly withdrew due to environmental hazards. Now, reopening certain sites is met with pushback from communities that would face health risks from industrial operations.

6. **Shift Towards Networking Over Skill Acquisition**: An increased focus on personal connections as economic levers undermines genuine skill development. Young people often view education as a means to access networks rather than a pathway to knowledge. This phenomenon appears prevalent in regions like the Middle East, where young men may neglect studies due to the belief that only family connections yield success, while girls excel because of their academic efforts.

This list serves as a starting point for understanding the complex challenges preventing the US from revitalizing its manufacturing sector. I encourage readers to contribute additional insights in the comments.

_____

1 The title of the bill reflected hesitation to fully embrace vigorous governmental intervention in the economy, despite ongoing lobbying and ad hoc measures. According to the White House:

Two years ago, President Biden signed the Inflation Reduction Act, with Vice President Harris casting the decisive vote in Congress. The IRA represents a key part of the Biden-Harris administration’s agenda to foster economic growth, creating good-paying jobs and lowering costs for Americans.

Already, the IRA has transformed American lives by negotiating lower prescription drug prices with Big Pharma, making the largest investment in clean energy in history, creating hundreds of thousands of jobs, and making the tax system fairer.